Money, the lifeblood of economies, is a carefully crafted entity that underpins modern societies. The process of how money is made involves intricate steps that intertwine technology, security, and artistic design. From the selection of materials to the printing techniques employed, each aspect is honed to perfection. But have you ever wondered about the secret methods utilized to safeguard currency against counterfeiters and ensure its trustworthiness in the hands of billions worldwide? The journey of money creation unveils a fascinating world where artistry meets technology in the name of commerce.

Key Takeaways

- The U.S. Department of Treasury oversees the production process of money.

- Currency paper is made from a durable blend of cotton and linen fibers.

- Skilled engravers design intricate security features to prevent counterfeiting.

- Quality control measures and advanced technologies maintain the integrity of currency circulation.

Money Production Process Overview

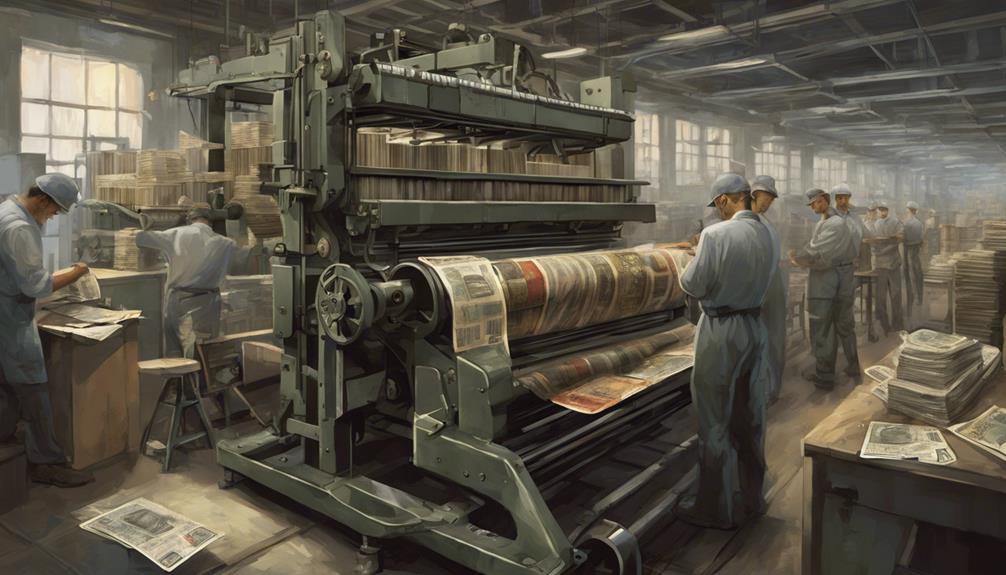

The process of producing money, overseen by the U.S. Department of Treasury, involves specialized materials such as currency paper made from a blend of cotton and linen. This choice of material enhances the durability of the bills, making them more resistant to wear and tear. Additionally, meticulous design selection is crucial, with security features integrated into the bills to prevent counterfeiting. The Bureau of Engraving and Printing, a part of the Department of Treasury, is responsible for the intricate designs and printing of paper bills. These designs include various security features like watermarks, color-shifting ink, and security threads to ensure the authenticity of the currency. The Federal Reserve Bank then distributes the printed money to financial institutions across the country. This systematic approach to money production ensures that the currency in circulation is both durable and secure, maintaining trust in the financial system.

Raw Materials for Money Production

Utilizing carefully selected raw materials is fundamental to the production of secure and durable currency. Printed money is typically made from a blend of cotton and linen fibers to create paper bills, while coins are crafted from metal alloys such as copper, nickel, and zinc. The unique combination of cotton and linen in paper money not only provides durability but also gives it a distinct texture that is difficult to replicate. On the other hand, metal alloys are melted and shaped into coins, ensuring their longevity and robustness in circulation.

To highlight the importance of raw materials in money production, consider the following table:

| Raw Materials | Types |

|---|---|

| Paper Bills | Cotton and linen blend |

| Coins | Metal alloys (e.g., copper, nickel, zinc) |

The quality of these raw materials is paramount in preventing counterfeiting attempts and maintaining the integrity of the monetary system. By carefully selecting the materials used in the production process, authorities can enhance security measures and safeguard against fraudulent activities.

Currency Design and Development

Currency design and development involve intricate engravings and advanced security features aimed at enhancing the integrity of the monetary system and deterring counterfeiting activities.

Key Aspects of Currency Design and Development:

- Engraving Process: Skilled engravers meticulously create intricate designs on steel dies, which are crucial for producing printing plates used in currency production. The collaboration between designers and engravers ensures the accurate transfer of detailed designs onto these steel plates.

- Incorporation of Security Features: Anti-counterfeiting measures such as watermarks, security threads, and color-shifting inks are integrated into the currency design. These features not only enhance the aesthetics of the currency but also serve as deterrents against fraudulent replication.

- Focus on Advanced Security: The currency design and development process prioritizes the integration of cutting-edge security features to uphold the trustworthiness of the currency. By utilizing innovative techniques, the production of secure printing plates is ensured, maintaining the authenticity of the monetary system.

Offset Printing in Money Production

Incorporating offset printing into the production process enhances the visual appeal and security features of currency notes through precise color application. This technique is utilized in money production to add color to currency sheets efficiently. Detailed background images on currency notes are printed using unique colors through offset printing, ensuring a high level of security. The high-speed sheet-fed presses used in offset printing enable accurate color application and alignment on currency sheets. By employing offset printing, the visual appeal of currency is significantly enhanced, making it more aesthetically pleasing. Moreover, the security features of the currency are also bolstered through this method. Overall, offset printing plays a crucial role in the money production process by allowing for the efficient and consistent application of colors on currency sheets, ultimately contributing to the overall quality and integrity of the currency being produced.

Plate/Intaglio Printing Process

The Plate/Intaglio Printing Process in currency production involves the meticulous creation of engraved steel plates with intricate designs to ensure the high-quality and secure printing of currency notes. This process is crucial for producing detailed and counterfeit-resistant banknotes. Here are some key aspects of Plate/Intaglio Printing:

- Engraving and Printing: Skilled artisans meticulously engrave intricate designs such as the inkwell freedom icon onto steel plates. These designs are essential for creating unique and recognizable currency notes.

- Federal Reserve Identification Numbers: Each plate used in the intaglio printing process is marked with specific Federal Reserve identification numbers. These numbers help track and authenticate the plates throughout the currency production process.

- Secure Printing: Intaglio printing applies ink to recessed areas on the plate, transferring the design onto paper with raised images. This method ensures the production of high-quality, detailed currency with unique tactile features, making it difficult to counterfeit.

Currency Inspection and Quality Control

During the currency inspection and quality control process, stringent measures are in place to identify and eliminate flawed bills and coins before circulation. The U.S. Department of Treasury plays a crucial role in overseeing the integrity and security of the currency production process. By conducting thorough inspections at various stages, the currency supply is safeguarded against counterfeit and substandard money entering the market.

Currency Inspection Process

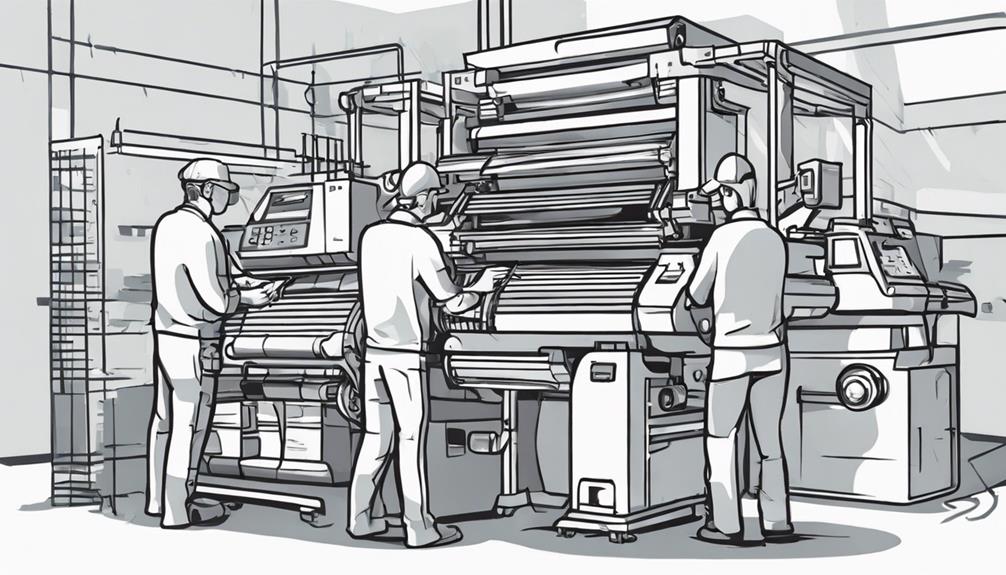

Utilizing state-of-the-art technologies and stringent quality control measures, the currency inspection process ensures the meticulous examination and segregation of defective notes to maintain the highest standards of quality in currency circulation. Advanced technologies play a crucial role in this process:

- Optical Currency Identification Systems (OCIS) are employed for high-speed and detailed inspection.

- Defective currency sheets are identified and segregated for further processing.

- The Single Note Inspection (SNI) system helps recover good notes from defective sheets to minimize errors in circulation.

These sophisticated equipment and quality control measures are essential to uphold the integrity of the currency supply and ensure only flawless notes enter circulation.

Quality Control Measures

In ensuring the integrity and quality of currency circulation, precision and meticulous scrutiny form the cornerstone of the quality control measures employed in currency inspection processes. Trained and skilled craftspeople utilize advanced technologies such as color-shifting ink and intaglio presses to authenticate currency. The presence of security features like the Federal Reserve seal is meticulously verified to prevent counterfeiting. Quality control measures are rigorously implemented throughout production, with press operators inspecting currency sheets every 500 impressions to uphold standards. Defective currency sheets are promptly identified and separated from the good sheets to maintain the high-quality standards demanded in currency production.

| Quality Control Measures | Description |

|---|---|

| Color-Shifting Ink | Utilized to enhance currency authentication |

| Intaglio Presses | Employed for intricate design printing |

| Federal Reserve Seal | Verified for authenticity |

| Trained Craftspeople | Ensure meticulous inspection |

Overprinting of Currency

The meticulous process of overprinting currency notes involves the precise addition of serial numbers, seals, and other crucial details to ensure their unique identification. This step is essential in the currency production process for maintaining security and authenticity. Overprinting is carried out using specialized letterpress printing techniques, ensuring precision and accuracy. Here are some key aspects of the overprinting process:

- Serial Numbers: Serial numbers are added during overprinting to track the circulation and authenticity of each currency note. These numbers play a vital role in identifying and differentiating individual notes.

- Seals and Security Features: Overprinting also includes the addition of seals and other security features using metallic ink. These features are designed to prevent counterfeiting and enhance the overall security of the currency.

- Final Details: Overprinting marks one of the final stages before currency notes are cut, trimmed, and packaged for distribution. It is a critical phase where each note receives its unique identifiers before entering circulation.

Cutting and Trimming Paper Money

Following the meticulous process of overprinting currency notes, the next crucial step involves the precision cutting and trimming of paper money to ensure uniformity and adherence to standard dimensions. Currency sheets, laden with freshly printed bills, undergo this critical phase using high-precision machines designed to slice through the sheets with accuracy and speed. The cutting machines operate automatically, swiftly transforming large stacks of currency sheets into individual bills. Trimming is equally essential, as it guarantees that each bill maintains a uniform size and shape, meeting the required standards. This process involves removing any excess paper surrounding the printed bills to achieve a clean and consistent finish. Once the cutting and trimming are completed, the bills are meticulously inspected, carefully packaged, and readied for distribution to various financial institutions. The combination of automated cutting processes and meticulous trimming ensures that every banknote is of uniform size and shape, meeting the stringent requirements for circulation.

Packaging of Printed Currency

Ensuring the integrity and secure distribution of freshly printed currency, the meticulous process of packaging plays a crucial role in safeguarding the banknotes during transit to Federal Reserve Banks. The packaging of printed currency involves several key steps:

- Sealing and Labeling: Currency bundles are sealed securely to prevent tampering or unauthorized access. Each bundle is meticulously labeled to provide necessary information for tracking and identification during transportation.

- Protection During Transit: Proper packaging processes are implemented to protect the currency bundles from damage. This includes using durable materials and techniques to ensure the banknotes remain intact and undamaged throughout their journey.

- Secure Transportation: Once packaged, the currency bundles are ready for secure transportation to Federal Reserve Banks. Specialized protocols and security measures are in place to guarantee the safe delivery of the banknotes, minimizing the risk of theft or loss during transit.

Distribution of Paper Money

Distribution of paper money occurs through a regulated process overseen by the U.S. Department of Treasury. Once paper currency is produced, it is distributed to Federal Reserve Banks, which act as the central bank of the United States. These Federal Reserve Banks then distribute the currency to various financial institutions across the country. Financial institutions, such as commercial banks, then provide the paper money to businesses and individuals for everyday transactions. This distribution process is crucial in ensuring the smooth flow of currency within the economy.

The U.S. Department of Treasury plays a vital role in monitoring the distribution of paper money to prevent counterfeiting and maintain the integrity of the currency. Additionally, part of the distribution process involves replacing worn-out or damaged currency in circulation with new bills. This meticulous approach to distributing paper money helps uphold the security and stability of the financial system.

Circulation of Physical Currency

The maintenance of the integrity and quality of physical currency in circulation involves a meticulous process of inspecting and replacing flawed bills and coins to ensure the smooth functioning of the economy. The currency inspection system is crucial to guarantee that only genuine and undamaged money is in circulation. Here are three key aspects related to the circulation of physical currency:

- Currency Inspection: Before distribution, money undergoes thorough inspection to detect any flaws or counterfeiting attempts. This ensures that only legitimate currency enters circulation, maintaining trust in the monetary system.

- Destruction of Flawed Bills: Flawed bills and coins are identified and removed from circulation. These damaged or counterfeit notes are securely destroyed to prevent their reentry into the economy, safeguarding its stability.

- Replacement Process: The U.S. Department of Treasury, along with the Federal Reserve Banks, oversees the replacement of worn-out or damaged currency as needed. This continuous monitoring and replacement system help to keep the currency supply fresh and reliable for daily transactions.

Ensuring Currency Security

Enhancing currency security involves the incorporation of watermarks, colored threads, and specialized inks during the currency production process. These features serve to deter counterfeiting attempts by making replication difficult. Additionally, microprinting, intricate designs, and unique security features such as color-shifting inks are employed to safeguard the integrity of the currency supply.

Currency Printing Techniques

Utilizing advanced printing techniques such as offset and intaglio, currency production is meticulously executed to ensure robust security features are integrated seamlessly into banknotes.

Key Points:

- Offset printing adds color to currency sheets simultaneously, streamlining production processes.

- Intaglio printing utilizes engraved plates to create raised images on paper, commonly used for high-value documents like currency.

- Specialized inks and printing techniques are employed to enhance security measures and deter counterfeiting attempts.

These methods, combined with detailed background designs and high-speed sheet-fed presses, contribute to the creation of intricately designed banknotes with sophisticated security features, making it challenging for counterfeiters to replicate.

Anti-Counterfeiting Measures

Incorporating advanced security features into currency design is imperative to safeguard against counterfeiting attempts and uphold the integrity of the monetary system. Watermarks added during the papermaking process, colored threads integrated into the paper, special inks, and detailed engravings are among the anti-counterfeiting measures employed. These features make replication difficult, deterring counterfeiters from producing fake money. By utilizing intricate designs on bills and coins, governments ensure the security of their currency. Government oversight plays a crucial role in maintaining the value and security of the currency, ensuring that robust anti-counterfeiting measures are in place. Overall, these measures enhance the security and trust in the monetary system, protecting it from illicit activities.

Importance of Money Production Regulations

Implementing stringent money production regulations is paramount to safeguarding the integrity of currency and preventing counterfeiting. To ensure the effective regulation of money production, the following measures are essential:

- Authorized Entities: Regulations dictate that only authorized entities, such as the U.S. Mint and the U.S. Bureau of Engraving and Printing, are permitted to produce money. This restriction helps maintain the security and authenticity of the currency.

- Compliance and Safeguarding Value: Compliance with regulations is crucial as it helps safeguard the value of money and upholds public trust in the currency. By adhering to set guidelines, the risk of counterfeiting and other fraudulent activities is significantly reduced.

- Oversight and Protection: The oversight provided by the U.S. Department of Treasury plays a vital role in ensuring that money production regulations are strictly followed. This oversight is essential for protecting the currency's value and integrity, as well as for preventing any attempts to undermine its security.

Frequently Asked Questions

How Is Money Actually Made?

Currency production involves a meticulous minting process at the U.S. Mint and Bureau of Engraving and Printing. Security features, such as watermarks and specialized inks, are integrated to deter counterfeiting. The economic impact of money production is significant, influencing monetary policy and financial stability. Flawed currency is destroyed, ensuring only high-quality bills and coins circulate, maintaining trust in the monetary system.

How Money Is Made Step by Step?

The minting process involves the creation of currency through intricate steps such as designing, engraving, and printing. Security features, like special inks and holograms, are integrated to deter counterfeiting. Printing technology advancements ensure precision and quality. The circulation of cash impacts economic stability, influencing inflation rates. Central banks regulate legal tender to maintain financial integrity. Understanding these processes is crucial for comprehending the complexities of money production and its role in the economy.

What Is Money Made Out Of?

Currency composition refers to the materials used in manufacturing money. Typically, paper currency is made from a blend of cotton and linen. This unique combination offers durability and distinctive texture, making it difficult to counterfeit. The use of these materials also ensures longevity and resistance to wear and tear during circulation. The composition of money plays a critical role in maintaining the security, integrity, and longevity of the currency.

Why Can't We Just Print More Money?

Simply printing more money without economic growth can have dire consequences. This action can lead to inflation risks, currency devaluation, and even hyperinflation, posing significant dangers to the economy. Governments must carefully manage money supply through monetary policy to maintain stable prices and economic growth. The balance between money supply and economic activity is crucial for ensuring a healthy and stable economy.

Conclusion

In conclusion, the process of money production is a meticulous and carefully regulated procedure that involves multiple steps to ensure the quality and security of the currency. From the selection of raw materials to the distribution of the final product, every aspect is closely monitored to prevent counterfeiting and maintain the integrity of the monetary system. As the saying goes, "money makes the world go round," highlighting the essential role that currency production plays in our daily lives.