Money, the lifeblood of modern economies, is a carefully crafted product of precision and security measures. The intricate methods employed in producing physical currency, overseen by government agencies, involve a blend of artistry and technology to deter counterfeiters and ensure trust in the monetary system. Understanding the meticulous steps involved in creating money unveils a world where innovation meets tradition, where every detail matters in upholding the integrity of our financial transactions. The journey from raw materials to circulating banknotes is a fascinating process that sheds light on the hidden intricacies of our monetary system.

Key Takeaways

- Currency production involves meticulous processes overseen by the U.S. Department of Treasury.

- Security features like watermarks and color-shifting ink are integrated to prevent counterfeiting.

- Advanced printing techniques like offset and intaglio printing ensure vibrant designs and high security.

- Skilled professionals inspect, package, and distribute currency to maintain its integrity and prevent counterfeiting.

Who Produces Physical Currency

Physical currency in the United States is meticulously produced by the U.S. Department of Treasury, with distinct responsibilities divided between the U.S. Mint for coins and the U.S. Bureau of Engraving and Printing for paper money. The Bureau of Engraving and Printing is tasked with the production of paper money, ensuring that the currency paper used is durable and incorporates various security features to prevent counterfeiting. The intricate designs on the bills are chosen by the Secretary of the Treasury, not only for aesthetic appeal but primarily to enhance security measures. By using specialized materials like a cotton and linen blend for the currency paper, longevity and resilience are imparted to the bills. Moreover, the inclusion of metallic or color-shifting ink in newer bills serves as an effective deterrent against counterfeiters, as these features are difficult to replicate accurately. The Bureau of Engraving and Printing plays a crucial role in safeguarding the integrity of the U.S. currency through meticulous attention to detail and advanced security measures.

The Materials Required for Currency Production

Currency production is a meticulous process that demands the use of specialized materials like cotton-linen paper and unique inks to deter counterfeit attempts. These materials are essential for incorporating intricate security features such as watermarks and colored threads, enhancing the currency's resilience against fraud. Understanding the significance of these materials and security measures provides insight into the meticulous manufacturing process behind creating trustworthy currency.

Currency Production Materials

In the intricate process of currency production, the creation of durable and secure banknotes necessitates the use of a specialized paper blend composed of cotton and linen. This unique paper provides the necessary durability for everyday use while also offering a level of security that is vital in preventing counterfeiting. Special inks are employed to craft intricate designs that are hard to replicate, further enhancing the security features of the currency. Watermarks, integrated during the papermaking process, add an additional layer of security, making it harder for counterfeiters to reproduce accurate copies. Additionally, colored threads woven into the currency paper serve as yet another security measure, contributing to the overall complexity of currency production materials and deterring fraudulent activities.

Security Features Importance

The selection and integration of specific security features play a crucial role in the production of currency, ensuring its resilience against counterfeiting attempts. Various security features such as watermarks, color-shifting ink, microprinting, and the use of specialized inks are incorporated into currency to deter counterfeiters. These features make it challenging for counterfeiters to replicate the intricate designs and details present in genuine currency. The integration of security threads further enhances the complexity of reproducing currency accurately. By utilizing these advanced security measures in currency production, authorities aim to safeguard the integrity of the monetary system and protect the public from fraudulent activities.

| Security Features | Importance |

|---|---|

| Watermarks | Added layer of security |

| Color-shifting ink | Difficult to replicate |

| Microprinting | Challenging for counterfeiters |

| Specialized inks | Enhances security features |

| Security threads | Complexity in reproduction |

Manufacturing Process Overview

Utilizing a precise blend of specialized materials, the manufacturing process for currency production intricately combines cotton and linen to form the foundation of paper money. This paper is then enhanced with security features like watermarks, holograms, and serial numbers to deter counterfeiting. Additionally, metallic or color-shifting inks are utilized in newer bills to provide added security measures. The production process also involves creating printing plates with intricate designs that are used to transfer the images onto the currency. Oversight by entities such as the U.S. Department of Treasury ensures that the money production process adheres to stringent quality and security standards, safeguarding the integrity of the currency.

Process of Making Paper Money

Crafting paper money involves a meticulous process that combines specialized materials and intricate design techniques to ensure security and durability. Engravers meticulously design intricate patterns and images on steel plates, employing advanced engraving techniques to prevent counterfeiting. These steel plates are then used in printing presses along with special inks to transfer the designs onto the paper money. Incorporating security features such as watermarks, the printing process ensures intricate details that are difficult to replicate. Additionally, colored threads are embedded within the paper during production, adding another layer of security to the currency. The entire production process is carefully monitored by the U.S. Bureau of Engraving and Printing to maintain quality standards and prevent fraud. By combining these elements – from engraving on steel plates to utilizing specialized inks and security features – the production of paper money results in durable, secure currency that is challenging to counterfeit.

Currency Design and Features

In order to bolster the security and anti-counterfeiting measures of paper currency, meticulous attention is devoted to incorporating intricate designs and advanced security features within the currency's overall design. This process involves the use of specific techniques and features such as:

- Engraving and Printing: Currency designs include intricate engravings and background images created through intaglio printing, which adds depth and detail to the design, making replication challenging for counterfeiters.

- Security Features: Watermarks, holograms, color-shifting inks, and other security features are integrated into currency designs to enhance authenticity and deter counterfeiting attempts effectively.

- Unique Elements: Special inks and printing methods are utilized to produce distinct features on various currency denominations, such as the inkwell freedom icon, ensuring that each bill has unique characteristics that are difficult to replicate.

The incorporation of these elements by institutions like the Federal Reserve Bank ensures the integrity and security of currency sheets, making it harder for counterfeiters to produce fake money successfully. These advanced security measures play a crucial role in maintaining trust in the monetary system and protecting the value of the currency.

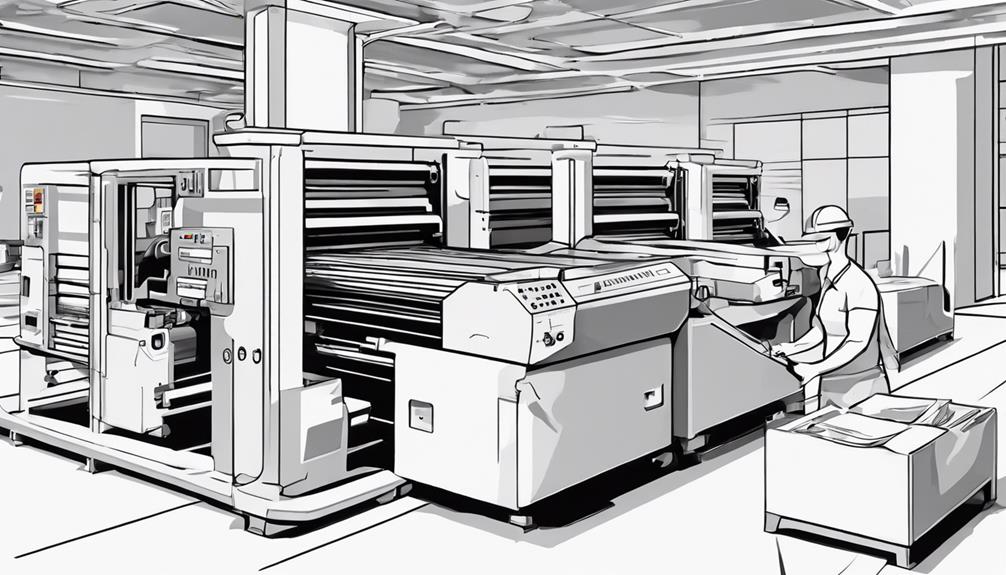

Offset Printing for Currency Production

Incorporating offset printing in currency production enhances the visual complexity and security features of currency sheets. This method is commonly used to introduce vibrant designs and intricate background patterns to currency, contributing to its aesthetic appeal and anti-counterfeiting measures. High-speed sheet-fed presses are employed to execute offset printing efficiently, allowing for the simultaneous application of multiple colors with precision and alignment. Offset printing is often combined with intaglio printing, a technique that creates detailed and raised images on currency. By integrating these printing methods, currency producers achieve a harmonious balance between design intricacy and security features. The use of offset printing in currency production plays a crucial role in ensuring that modern banknotes are not only visually appealing but also equipped with sophisticated security elements that make them challenging to counterfeit.

| Offset Printing in Currency Production | |

|---|---|

| Advantages | Enhances visual complexity and security |

| Techniques | Simultaneous color application |

| Equipment | High-speed sheet-fed presses |

| Complementary Method | Intaglio printing for detailed images |

| Purpose | Achieving vibrant designs and anti-counterfeiting measures |

Plate/Intaglio Printing Process

The Plate/Intaglio Printing Process in currency production involves the meticulous engraving of intricate designs onto steel plates to create raised images on paper. This process is essential for ensuring the security and authenticity of banknotes. Here are key aspects of the Plate/Intaglio Printing Process:

- Engraved Plates: Skilled artisans engrave intricate designs on steel plates with precision to transfer these designs onto the paper during printing.

- Intaglio Presses: Specialized printing presses use these engraved plates to apply ink onto the paper, resulting in raised images that can be felt by touch.

- Anti-counterfeiting Features: The detailed designs and raised images created through this process are crucial elements in banknote security. These features, such as the Federal Reserve seal, make counterfeiting more challenging and help in the detection of fake currency through the Currency Inspection System.

The Plate/Intaglio Printing Process plays a significant role in producing high-security currency with intricate details that are not easily replicated, contributing to the overall integrity of the monetary system.

Inspection and Circulation of Currency

Following the meticulous Plate/Intaglio Printing Process in currency production, the inspection and circulation of currency play a crucial role in maintaining the quality and security of the monetary supply. Highly trained and skilled professionals meticulously inspect each banknote using sophisticated equipment to ensure adherence to stringent quality standards. The Overprinting Processing Equipment, equipped with advanced technology, verifies Federal Reserve identification numbers and detects any anomalies in the printing process. Crane Currency in Dalton is one such facility known for its expertise in currency inspection and verification.

The inspection process is vital for identifying counterfeit or damaged currency, which is subsequently removed from circulation to uphold the integrity of the monetary system. Genuine notes and coins that pass the rigorous inspection are then packaged using specialized Processing Equipment and Packaging, ready for distribution to banks and financial institutions. This meticulous process guarantees that only authentic currency, imprinted with ink for the freedom, is circulated, reinforcing trust in the money-making system.

Packaging and Distribution of Physical Money

The packaging and distribution of physical money involve precise bundling, sealing, and tracking processes to ensure the security and integrity of currency during transportation. Federal Reserve Banks meticulously package cash in bundles secured with straps and seals before distributing them to financial institutions, which then receive ordered amounts based on demand and circulation needs. This meticulous process is essential for maintaining the accuracy and security of physical money in circulation.

Printing Process Overview

In the process of preparing physical money for circulation in the economy, the packaging and distribution stages play a vital role in ensuring the secure and organized transfer of bills and coins to various financial institutions and Federal Reserve Banks. After the printing process, physical money undergoes cutting, trimming, and packaging procedures before distribution. Here are key aspects of the packaging and distribution process:

- Secure Wrapping: Bills or coins are securely wrapped and sealed for transportation.

- Specialized Packaging: Specialized equipment is used to ensure the safe and organized transfer of physical money.

- Distribution: Physical money is distributed to financial institutions and Federal Reserve Banks to maintain liquidity in the financial system and ensure access to currency for businesses and individuals.

Security Features Explained

How are the intricate security features integrated into the packaging and distribution process of physical money to safeguard against tampering and ensure the integrity of currency circulation? To enhance security, printing techniques merge with trained and skilled craftspeople to embed features like background colors and the 'bell in the inkwell' to deter counterfeit attempts. Before distribution, untrimmed printed sheets are carefully inspected to ensure accuracy and prevent unauthorized alterations. These security measures are crucial in maintaining the trustworthiness of physical money. By incorporating these advanced features, the currency is fortified against forgery and counterfeiting attempts, guaranteeing the safety of transactions and preserving the value of the monetary system.

Transporting Cash Securely

Integrating stringent security measures during the packaging and distribution process of physical money is essential to safeguard against theft and ensure the smooth and secure transit of currency.

Key Points:

- Physical money is securely packaged in containers like canvas bags or plastic cassettes for transportation.

- Armored vehicles with enhanced security features are utilized for transporting physical money between banks, ATMs, and businesses.

- Cash-in-transit companies specialize in securely moving large amounts of printed currency to various locations to ensure safe delivery.

Utilizing electronic tracking systems, GPS technology, and following strict protocols are crucial steps in preventing theft, loss, or counterfeit activities during the transportation and distribution of physical money.

Frequently Asked Questions

How Is Money Actually Made?

Currency production involves coin minting and paper printing under the oversight of central banks like the U.S. Mint and Bureau of Engraving and Printing. Security features such as watermarks and holograms safeguard against counterfeiting. The monetary value of each currency is determined by central banks. Flawed bills and coins are destroyed to maintain quality. The economic impact of currency production is significant, influencing inflation rates and overall financial stability.

How Money Is Made Step by Step?

The currency creation process involves intricate steps to ensure the production of secure and high-quality money. These steps include the minting process for coins and paper production for bills. Printing presses are used to transfer designs onto currency, incorporating essential security features. The entire manufacturing process is closely monitored to adhere to strict monetary policy guidelines. Flawed currency is promptly destroyed to maintain the integrity of the money supply in circulation.

What Is Money Made Out Of?

Money is primarily composed of a unique blend of cotton and linen for paper bills and metals like copper, nickel, and zinc for coins. These materials are carefully selected to ensure durability, security, and resistance to counterfeiting. The design and composition of currency play a vital role in its production techniques, incorporating various security features and design elements. Understanding the materials used in money production is crucial for comprehending its economic implications.

Why Can't We Just Print More Money?

Expanding the money supply without corresponding economic growth raises the risk of inflation. Such actions can lead to currency devaluation and hyperinflation, causing severe economic consequences. Increasing government debt and eroding public trust in the currency are additional concerns. Central banks use monetary policy to regulate money supply, aiming to maintain stable prices and economic growth. Controlling the money supply is crucial to prevent economic instability and preserve the purchasing power of the currency.

Conclusion

In conclusion, the intricate process of producing physical currency involves meticulous attention to detail and advanced security measures to prevent counterfeiting. The combination of specialized materials, engraving techniques, and printing methods ensures the quality and integrity of the currency. Despite the complexity of currency production, it is a necessary component of our financial system. So next time you hold a bill in your hand, remember the effort and precision that went into creating it.